We are proud to highlight our successful delivery of a major Mechanical, Electrical, and Plumbing (MEP) project for TNS Beaconhouse School. This highly specialized project involved the comprehensive installation of a 353 Ton Midea Variable Refrigerant Flow (VRF) system, complete with precision copper piping, robust structural hanging, and system commissioning.

This critical upgrade provides the students, faculty, and administrative areas of TNS Beaconhouse with a high-performance, energy-efficient, and customized climate control solution, essential for a modern, focused learning environment in Pakistan.

🛠️ Project Scope: Precision VRF System Deployment

The Midea VRF system is a modern solution chosen by TNS Beaconhouse School for its efficiency and ability to provide simultaneous heating and cooling to different zones within the building. Our scope of work covered the following professional phases:

1. Supply and Installation of 353 Ton Midea VRF System

- High-Capacity VRF Units: We supplied and installed multiple Midea VRF outdoor units totaling a massive 353 Tons of cooling capacity. The VRF technology allows for variable speed compressor operation, which significantly reduces energy consumption compared to traditional AC systems.

- Zoned Climate Control: The system was strategically linked to hundreds of Midea indoor units throughout the school. This ensures that classrooms, labs, offices, and common areas at TNS Beaconhouse can have their temperatures controlled independently, optimizing comfort and reducing energy waste in unoccupied spaces.

- Efficiency for Education: Implementing this system directly supports the school’s long-term sustainability goals by providing high-efficiency air conditioning required for year-round comfort.

2. Complete Copper Piping Installation

- Precision Refrigerant Network: The backbone of the VRF system is its complex network of refrigerant lines. We executed the complete installation of high-grade copper piping, connecting all outdoor units to every indoor unit across the expansive campus of TNS Beaconhouse.

- Expert Flaring and Brazing: All pipe joints were meticulously flared and professionally brazed (welded) to guarantee a 100% leak-proof system. Maintaining system integrity is paramount for VRF efficiency.

- Thermal Insulation: Every copper pipe was correctly insulated with UV-resistant, fire-rated insulation. This crucial step prevents cooling loss and safeguards the system’s efficiency, a necessity in Pakistan’s varying temperatures.

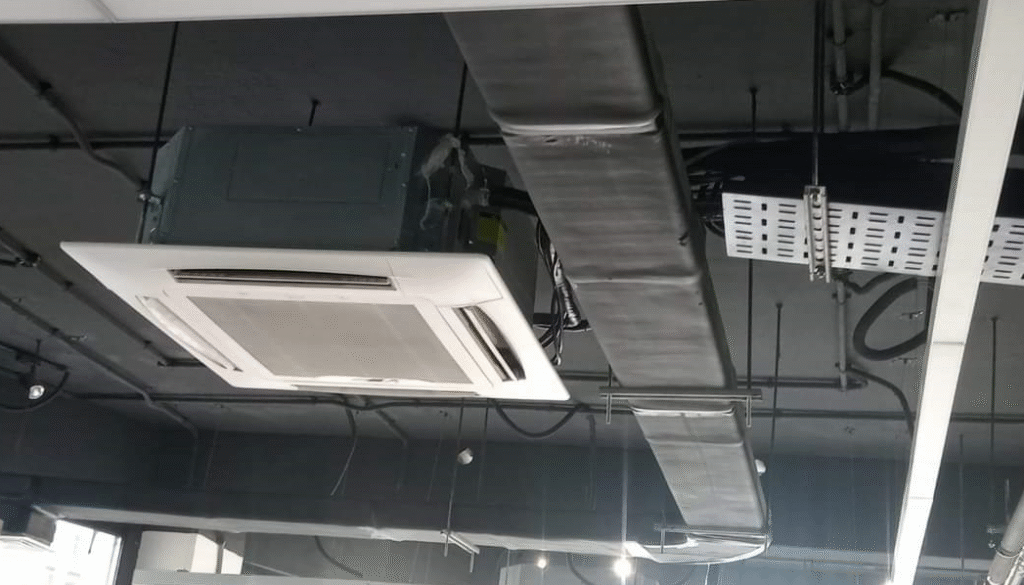

3. Structural Hanging and Support System

- Secure Infrastructure: We designed and installed a robust hanging and support system to securely anchor the heavy VRF outdoor units and the extensive network of copper piping and electrical conduits.

- Safety and Longevity: The framework was constructed using corrosion-resistant materials, ensuring the entire system’s stability and safety over its lifespan. Proper installation minimizes stress on the piping, extending the longevity and reliability of the investment made by TNS Beaconhouse School.

- Minimal Disruption: The installation schedule was carefully managed to minimize disruption to the ongoing academic activities at TNS Beaconhouse.

Key Benefits for TNS Beaconhouse

| Feature | Professional Benefit | Advantage for TNS Beaconhouse |

| VRF Technology | Variable capacity control and simultaneous mode (heating/cooling). | Maximum energy savings and lower monthly utility bills. |

| 353 Ton Capacity | Scales to meet the thermal load of a large educational complex. | Uniform and consistent comfort across all large classrooms and halls. |

| Zoned Control | Individual temperature control for separate school areas. | Optimized learning environment and improved faculty/student well-being. |

| Copper Piping & Hanging | Guarantees system integrity, safety, and operational efficiency. | Reduced maintenance costs and reliable performance for years. |

This project at TNS Beaconhouse School showcases our commitment to delivering modern, high-tech, and sustainable HVAC solutions for the education sector.